PSS-Design

POPAI SUSTAINABILITY STANDARD - Design Strategies

- Design for disassembly/deconstruction

This strategy is intended to be used by designers to create products and units that can be dismantled and components separated for recycling at the end of their life.

- Light-weighting

Using this principle in design concepts, the item is designed to be as light as possible (whilst taking into account other constraints such as durability and structural strength).This increases the environmental performance of the unit as less weight often translates to less material content, less energy used in manufacture and a reduction in fuel use when transporting the units.

- Waste reduction

Here designers consider how the concepts created would result in the production of waste (through over-packaging, inefficient use of materials, inefficient energy use etc.) and try to redesign concepts to minimise waste.

- Lifecycle design

This strategy is used by designers to take into account the whole lifecycle of the products they design – i.e. consideration is applied to how the product or unit will have environmental impacts at each stage of the product’s life (extraction of raw materials, manufacture, transportation, packaging waste, energy use etc.). Life cycle design can improve a design’s overall circularity and ensures that you maximise the utility and life of materials used.

- Low energy product use

Using this concept, designers and product engineers attempt to create products to use energy efficiently and ensure that products only use energy where necessary.

- Product simplification

To increase the product’s environmental performance, this strategy encourages designers to reduce the number of different components and to simplify the designs. This then eases the manufacturing stage and saves on labour and material costs.

- Minimisation of different materials

By keeping the amount of different materials to a minimum, the recycling process is made easier as sorting different material types make the process more complex and often impedes recycling.

- Design for re-use

This strategy is something designers could use to ensure that products don’t end up in landfill. By designing a product, unit or component for re-use, it means a reduction in the need to manufacture new replacement parts and reduces the chance of the part being sent to landfill.

- Design for recycling

Again, this strategy could be used by designers in the concept stage to create products that can be recycled at the end of their useful life rather than automatically being sent as waste to landfill.

- Modular design

By designing products with a modular core, the external aesthetics and fascias can be removed and updated with a new external to create a fresh/renovated look. This results in less waste and cost as the internal modular components can be re-used time and time again.

- Design for updating (future-proof)

As above, products and units can be designed for updatability, in that when new technologies, materials or features are designed/made available, they can then be incorporated into the existing product frame, rather than having to manufacture a completely new unit.

- Specification of eco-preferable materials

When designing retail display, it is recommended to consider the use of alternative materials that impact less on the environment than traditionally-specified materials.Environmentally-preferable materials may fall into a variety of categories such as recycled content, biodegradable, organic, locally-manufactured, lower content of hazardous chemicals, natural fibres, sustainably sourced, high strength-weight ratio, results in minimal waste etc.

- Design for longevity and durability

Using this strategy, designers can create products that can last longer than similar traditional products, and thus reduce the need to replace the item. With more desirable products there is a lesser need to continually replace units through wear and tear. Designing products with higher durability can reduce the need for maintenance visits and the recall of faulty units.

- Circularity (closed loop cycle of material use)

This principle aids the designer in considering how the materials they specify could be part of a closed-loop cycle. Traditionally, products are made from materials extracted from the Earth, formed into a product, used and then disposed of in landfill. This would be known as the material line. With a closed loop, or circularity, materials are extracted, formed into products, and then at the end of their life, recycled into other materials for use in new product. This system reduces the need for landfill and also the harmful extraction of raw materials.

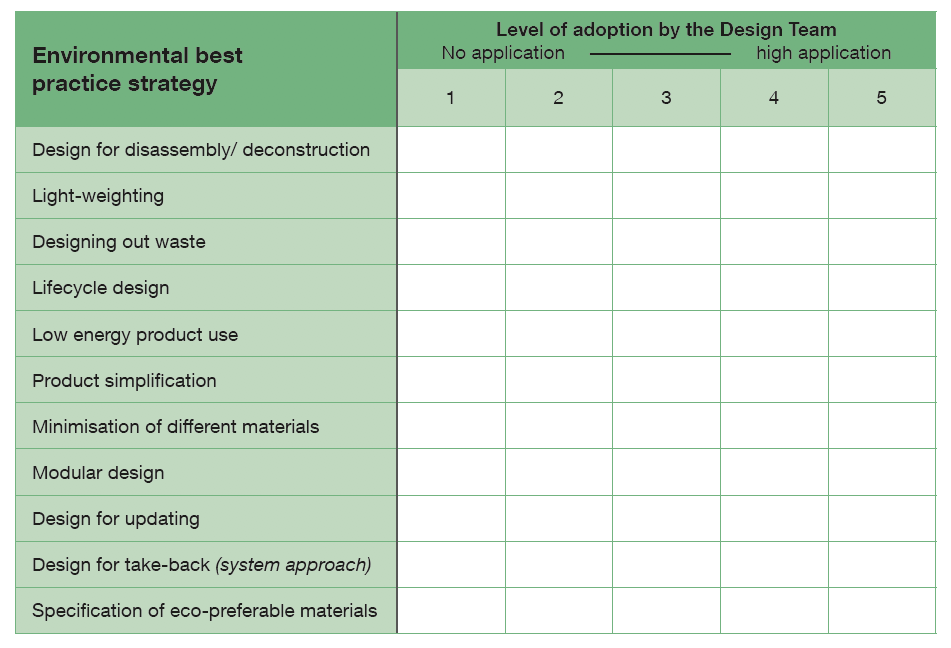

Level of engagement and application of environmental strategies

The following table can be used to summarise the level of engagement from your design team.