Heat Bending is a commonly used process for turning sheet materials into folded objects. A sheet of plastic is laid over a hot metal rod or wire, with barriers put in place where the heat is not required. It is then heated for a set amount of time until the plastic is malleable before being bent to the correct angle and held in place using a jig, if required. Multiple bends can be created in a single turn to create reasonable complex parts.

Reasonably thick sheets of plastic can be heat bent but key areas to watch out for are material distortion along the bends as well as discoloration of the material and burning if the temperature is too high. Most plastics can be heat bent but some can become brittle after the process.

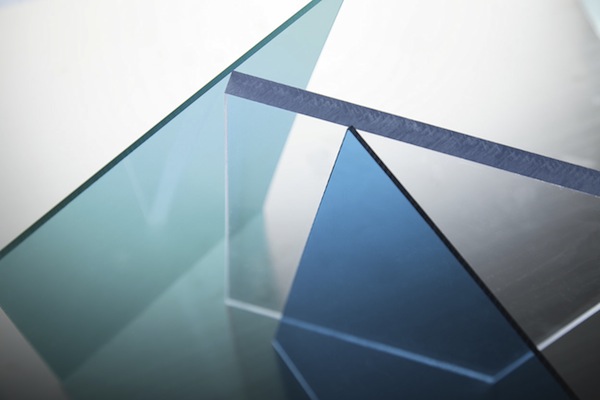

Below is a list of plastics materials suitable for heat bending.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|