Injection moulding is a commonly used mass manufacturing process for creating complex plastic parts. Plastic pellets are fed into a moulding machine, heated and then forced into a mould. The moulding process itself is complex, with factors such as pressure, heat, mould flow and cooling determining the successful creation of parts. The tools are made from metal (aluminium for small runs and hardened steel for long runs), which is precision cut to the shape of the desired part.

Tools can have multiple cavities to produce multiple parts per shot or a family of different parts. Injection moulded parts can be printed using a variety of processes from screen printing onto flat parts to pad printing for more complex surfaces. For small production runs injection moulding is an expensive option and can take weeks to produce.

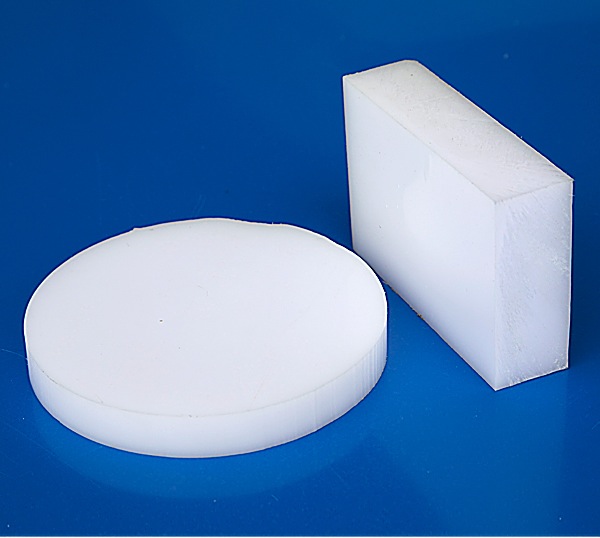

Below is a list of plastics materials suitable for use in injection moulding production methods.

|

|

|

|

Discover the material properties of Acrylic Click here>

|

|

|

|

|

|

|

|

View our gallery of P-O-P displays created with plasticsClick here>

|

See a short video of Injection Moulding in action.

Click here>

|

|